Two Key Challenges (and solutions) to Growth in the Freight Industry

The past 18 months have brought many aspects of our global community into sharper focus. From the need for robust public health responses to the necessity of digitization for remote work, the pandemic continues to disrupt established norms. One of the industries that continues to feel an outsized impact from rolling lockdowns, outbreaks and the recovery is the freight industry.

While many consumer and market segments have been focusing on health-related concerns and new organizational structures, the health of our global supply chain continues to be challenged. High-profile events like the blockage in the Suez Canal or the closure of critical shipping centers in Shenzhen and Guangzhou are emblematic of an industry that is facing headwinds that are unrelated to demand. Building supplies, consumer goods, and food items are all increasing in price due to supply chain shortages, and experts aren’t predicting improvements anytime soon.

In order for stakeholders throughout the global supply chain to achieve growth in this volatile landscape, it is crucial that they understand the major developments and challenges within the industry.

Significant Concern Regarding Labor Shortages

With all of the technological and engineering developments the supply chain industry has seen over the past few decades, it is hard to believe that this level of delay is possible. But, even a cursory glance at the logistics landscape shows that one of the biggest issues is actually on the human side: labor shortages.

Throughout all components of the supply chain — sourcing, manufacturing, and distributing of products — there is a dearth of labor necessary to meet rising demand. In addition to driving up costs, this mass disruption is drastically increasing wait times and will likely lead to more serious issues down the road if left unaddressed. Two particular areas facing mass labor shortages are drivers and skilled technicians.

Skilled Technicians

In addition to the well known driver shortage in the industry, there is also a lack of skilled technicians. These professionals repair trucks, mechanical devices, and other essential components in the movement and delivery of goods. The trickle-down effects of this shortage are significant, as under-maintained vehicles and systems experience more downtime.

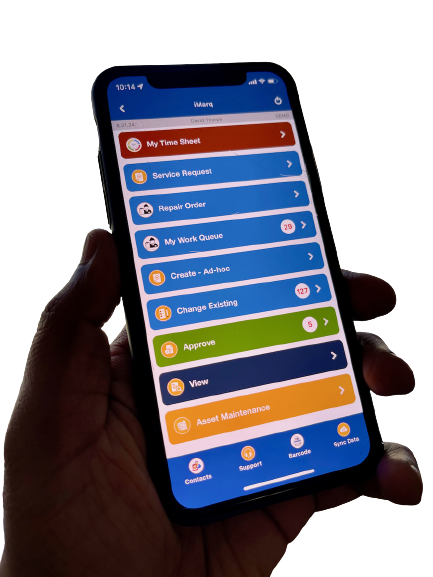

Pre-pandemic numbers show 38% of employers were struggling to fill roles — that number now sits above 50%. Turnover, absenteeism, and poor scheduling are all contributors to this increase, according to experts. If employers are going to adequately address these issues to help bolster the supply chain infrastructure, it is imperative that they adopt comprehensive digital solutions to address technician shortages.

With this type of labor scarcity, every minute of utilization counts – and it is inexcusable to let skilled techs waste their time waiting for parts, filling in forms, entering data into systems, and worst of all, trying to write copious notes and then trying to interpret handwriting (sometimes their own!).

Communications and Operational Efficiency are a Necessity Moving Forward

Like the human side of the freight industry, there are also numerous operational and communications inefficiencies that plague companies at an organizational level. Logistics and manufacturing rely on finely-tuned scheduling to balance all the moving components. Then there is also the issue of ensuring that machinery and vehicles are well-maintained and operating at the highest level.

The fixes

Technology can help.

One of the biggest inefficiencies within the freight industry is a lack of systems integration. Many of the operational and communications systems in these companies are outdated legacy solutions that keep information siloed. ELD/telematics, maintenance systems, parts/spares systems and crew scheduling & management are all housed in different systems with different interfaces; and there is an excessive use of paper in the workshop and on board. In addition to drastically increasing the likelihood of replication errors, outdated systems, paper and data entry also require additional administrative resources that could be automated through digital solutions.

The delicate nature of our global supply chain system is on full display as we continue to navigate the post-pandemic era. For freight industry stakeholders looking to address staffing shortages and organizational inefficiencies, comprehensive, systems-agnostic solutions that can be rolled out today (not in a year!) are ideal. If you’re looking to reduce cost, improve efficiency, and make your freight company more resilient during these uncertain times, reach out to the experts at Connixt today to learn more about our digital transformation solutions!